Have you ever wanted to build your own climbing wall in the comfort of your home? Not sure where to even begin?

Not to worry! Some of my close friends recently bought a new house and decided to build a climbing wall in their garage, so I got to witness the making of the wall every step of the way 😀

Here’s what we did…

Step 1: Befriend an architect (JK… but seriously)

If you know an architect, now is the time to befriend them. This project was significantly easier for us because we happened to already have an architect in our friend group who was super psyched on the home wall and designed the whole thing with his architectural talent.

Meet Aaron… architect extraordinaire. Aaron enjoys long walks on the beach, rock climbing, blackjack, and sci-fi fantasy novels. His idea of the perfect date is April 25th because it’s not too hot and not too cold… just kidding. He’s taken. Sorry, ladies!

If you don’t know an architect, don’t worry. I’ll tell you exactly what he did 😀

Step 2: Measure the area

This step should be fairly obvious, but I don’t know your life…

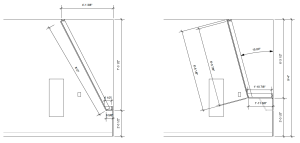

Step 3: Decide on the angle of the wall

If you’re building more than one wall, you might want to build them at different angles. For example, we built the system wall at 30 degrees and the campus board at 15 degrees.

From what I’ve read, the industry recommendation for the angle of a campus board is between 12 and 16 degrees, and a reasonable angle for a system wall is between 10 and 30 degrees, but you do you.

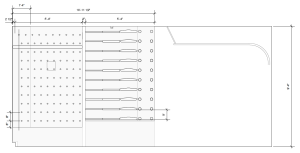

Step 4: Create a blueprint of your wall design & do some math

You can either sketch this onto some graph paper or draft it up with some fancy software like AutoCAD or Google SketchUp. Whatever you choose, be sure to note any gaps you want to leave, angles, and the thickness of the lumber you want to use.

These are our fancy schmancy designs crafted by Aaron Denton. Click to enlarge the photo.

Step 5: Buy materials and acquire equipment

The total amount of materials needed will depend on your individual home wall dimensions, but basic materials include:

- 2×4’s for the frame

- Sheets of plywood (4′ x 8′)

- Deck screws (at least 2.5″ long) for structure

- Dry wall screws (at least 1.25″ long) for attaching plywood

- L-brackets

- T-nuts

- Climbing holds and/or campus rungs

As with any DIY project, leave yourself some room for error, and buy a little more than you think you’ll need.

Each one of our training walls is 64-inches wide, which is one sheet of plywood plus an additional 16 inches, but you can make your walls as wide as you want.

According to Aaron the Architect, for every sheet of plywood that you plan on using, you’ll need 4 studs (2×4’s) spaced 16 inches apart, which comes out to 8 feet of 2×4’s. Fun fact.

Necessary equipment includes:

- Mechanical stud finder

- Table saw, skill saw, or circular saw

- Straight edge

- Pen

- Tape measure

- Level

- Drill

- 1/2″ drill bit

- Hammer

- Ear plugs

Step 6: Cut materials to size

Measure everything, and double check that your measurements match your design. It’s a good idea to use a straight edge to mark everything just so you don’t accidentally cut something at the wrong angle.

You have free reign on how you want to structure your wall, but we decided to go with an 8-inch grid on the system wall, and space the campus rungs 9 inches apart.

Aaron cut all the lumber at his office using a table saw, but you could get the job done with a skill saw or circular saw as well.

He drilled 1/2″ holes in the plywood using an 8″ grid, and we hammered T-nuts into the back of the plywood. This process was extremely loud and annoying. I highly recommend using heavy duty ear protection, unless you don’t like hearing things in life.

Step 7: Start building

When it’s time to start building, make sure you measure everything from the ceiling!!

Garage floors are almost ALWAYS sloped to help with water drainage. If you measure from the floor like we did, you will have a slightly sloped wall. You’ll still be able to use it, but it won’t be perfect… and I know that’s important to many of you 😉

Start by finding the studs with your handy dandy mechanical stud finder. Then, you can attach the frame to these studs in the walls and ceiling using the 1.25″ drywall screws.

Next, attach your vertical studs to your base frame with your 2.5″ deck screws, using L-brackets (when appropriate) to keep things flush.

Once the frame is secure, you can attach the sheets of plywood with the 1.25″ drywall screws.

We used the remaining pieces of plywood to make a kick board. You can drill holes in the kick board and hammer T-nuts onto the back if you want to add footholds for sit starts, or you can just buy some wooden rails and screw those onto the plywood as another option for feet.

Once you attach the kick board to the wall studs with drywall screws, it’s time to decorate your wall!

Step 8: Add holds and/or campus rungs

We decided to go with Atomik Climbing holds for the system wall, and Metolius WoodGrips for the campus rungs. We were going to make our own sloper rungs out of 24″ PVC pipe and sandpaper, but I ended up winning some Half Pipe campus rungs from Atomik’s weekly Instagram giveaway, so we nixed that idea!

Atomik has some amazing system wall packages and other accessories, but we ended up ordering a customized bundle of holds. This is what our order looked like:

- System Crimps

- System Slopers

- System Slopers Flat 100 degrees

- System Jugs

- System Domes 6″

- System Pinches

- System Pockets

- Yaniro Jugs

- Yaniro Pockets

- Yaniro Pinches

- Bolts

Ta daaaaa! We have a finished home wall. The end!

Mistakes to Avoid

Here are a few mistakes we made along the way that you can avoid for your home wall:

- Don’t let the architect’s girlfriend cut some of the lumber… as you risk building an uneven frame. Let one person do all the cutting for consistency’s sake.

- Don’t measure from the floor if you’re building a wall in your garage. As previously mentioned, garage floors are not level. We realized this a little too late, but we’re okay with a little imperfection.

- Don’t place a stud right behind a column of T-nuts. If you do this, you’ll render an entire column of T-nuts obsolete or you’ll have to chop some bolts to work around it.

Tips from the Architect

1. Before you get started, take a look at the room that will be housing your home wall. If the ceiling of this room is technically a floor for another room, then it will be strong enough to hold the weight of the wall and the climber.

However, if the ceiling of this room is a roof (i.e. there are no rooms above it), then it will not be strong enough to support the wall. This happens because floors are built to support the weight of people, whereas roofs are not.

If you’re dealing with a roof ceiling, you will want to attach the climbing wall to the side wall and/or the floor and avoid drilling into the ceiling.

2. If you want to avoid placing a stud behind your bolt holes, then plot your bolt holes on an 8-inch grid, starting 4 inches from one side. This will keep you from having to chop bolts.

3. Be careful making your own sloper campus rungs. Cutting PVC pipe vertically can be pretty challenging if you don’t know what you’re doing. If you don’t have experience cutting PVC, it might be safer to just purchase the Half Pipes from Atomik, or another manufacturer.

4. If you’re interested in building a Moon wall (a standardized system wall with precise layouts and workouts to go with them), check out this comprehensive guide from moonclimbing.com.